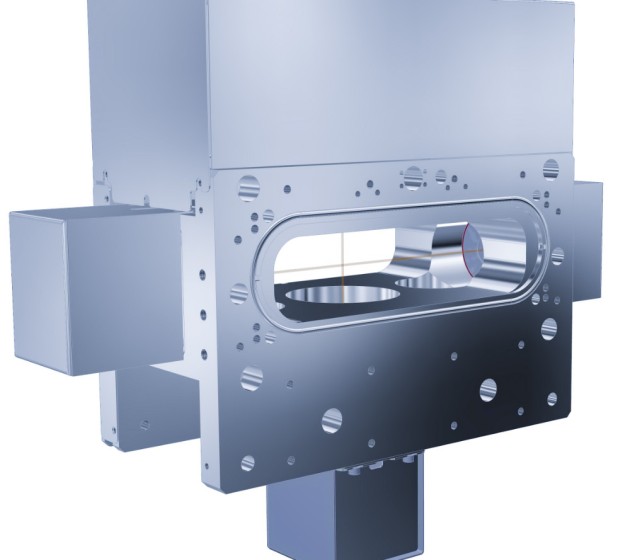

WAM WaferAlignment.Modules

The Adenso WAM200/300 VAC WaferAlignment.Module aligns substrates such as round and angular wafers, transparent substrates and carriers, centrally and in an angular position. The WAM is perfectly combinable with the Adenso WHR WaferHandling.Robot – the robot receives the correction data from the WaferAlignment.Module automatically via an interface.

Your advantages

- Footprint: space-saving thanks to direct integration in cluster systems

- Flexible: different substrate sizes and geometries are possible

- Productive: fast alignment

- Precise: via Adenso DDU direct drive unit

- Cost-cutting: saves investment and operating costs

AAM AutoAlign.Modules

The Adenso AAM AutoAlignment.Module enables the position accuracy of the EE end effector within a process to be checked without stopping or opening the system. This tool can very easily and precisely register the current position of the substrate gripper and correct it if necessary.

Turning the wafer in

the vacuum

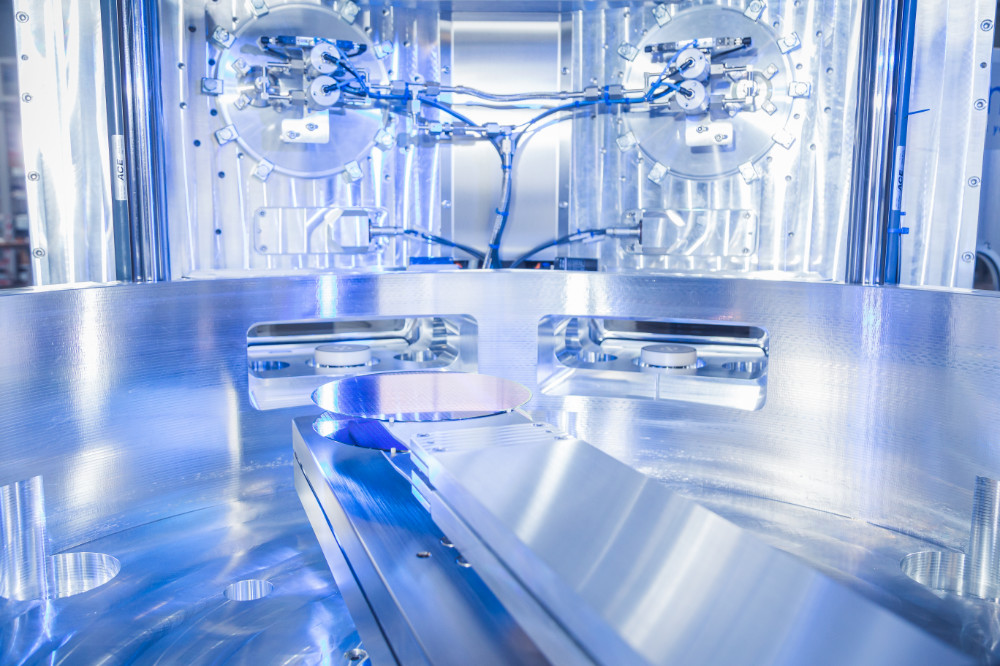

WFM WaferFlip.Modules

The Adenso WFM WaferFlip.Modules enable wafers to be turned over within the vacuum environment to process the back of the wafer.

- Turning wafers under vacuum

- Reliable solution for the processing from below

- Reduction of particle contamination

- Saves additional system equipment and cleanroom space and thus additional costs

- Time saving due to the connection of multiple processes within a system

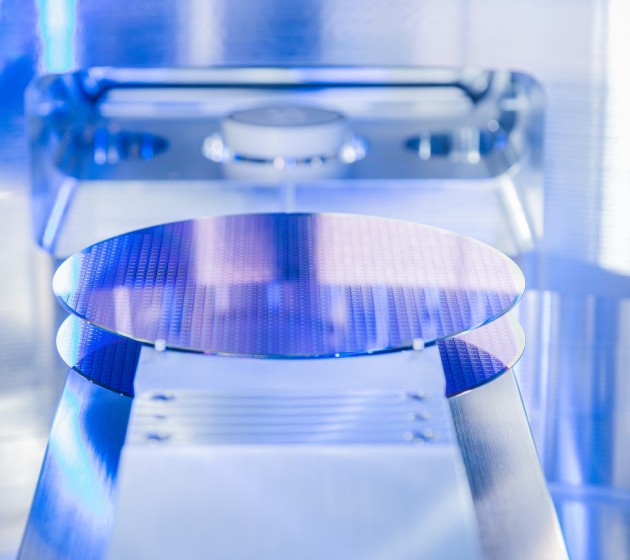

WXM WaferExchange.Modules

The customised Adenso WXM WaferExchange.Module allows wafer exchange directly in the vacuum. The special module separates the wafer from the carrier, exchanges the respective wafer and reconnects it with the carrier. The change is made without atmospheric contact within the system so that particle contamination is reduced significantly and processes are accelerated efficiently.

EEX EndeffectorExchange.Modules

The Adenso EEX EndeffectorExchange.Module is a complex, customised module for changing EE end effectors within the VAC.ROBOTICS platform.