adCONTROL – cluster control system

With the Adenso Cluster.Operating system, adControl, you receive a hardware-independent, PLC-based and flexible Software.Solution for control of the VAC.ROBOTICS platform. In MASTER.MODE, adControl includes an intuitively operable graphic user interface. Secure communication with your process control system takes place via the Adenso.Interface.

Control your CLUSTER.Solution very simply:

stand-alone system

Control hardware

Operation

Safety

Modules

Save

Command

Functions

Interface

Integration

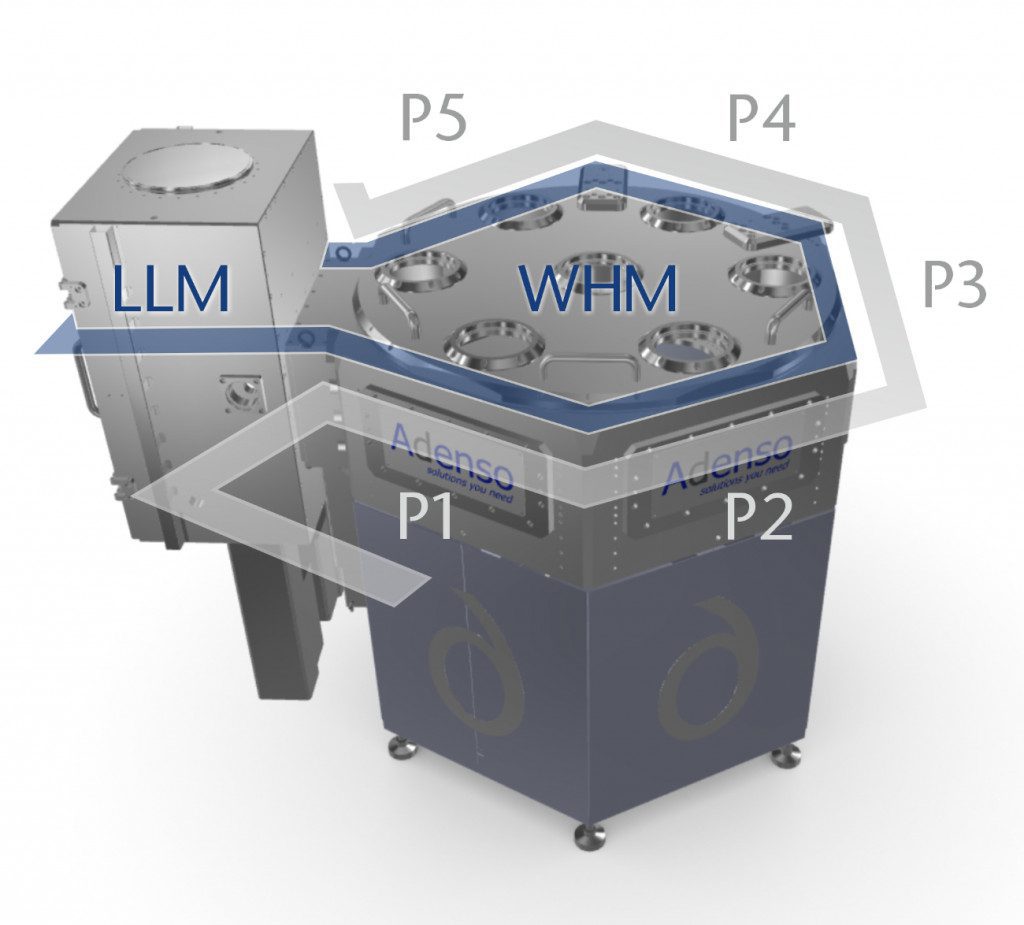

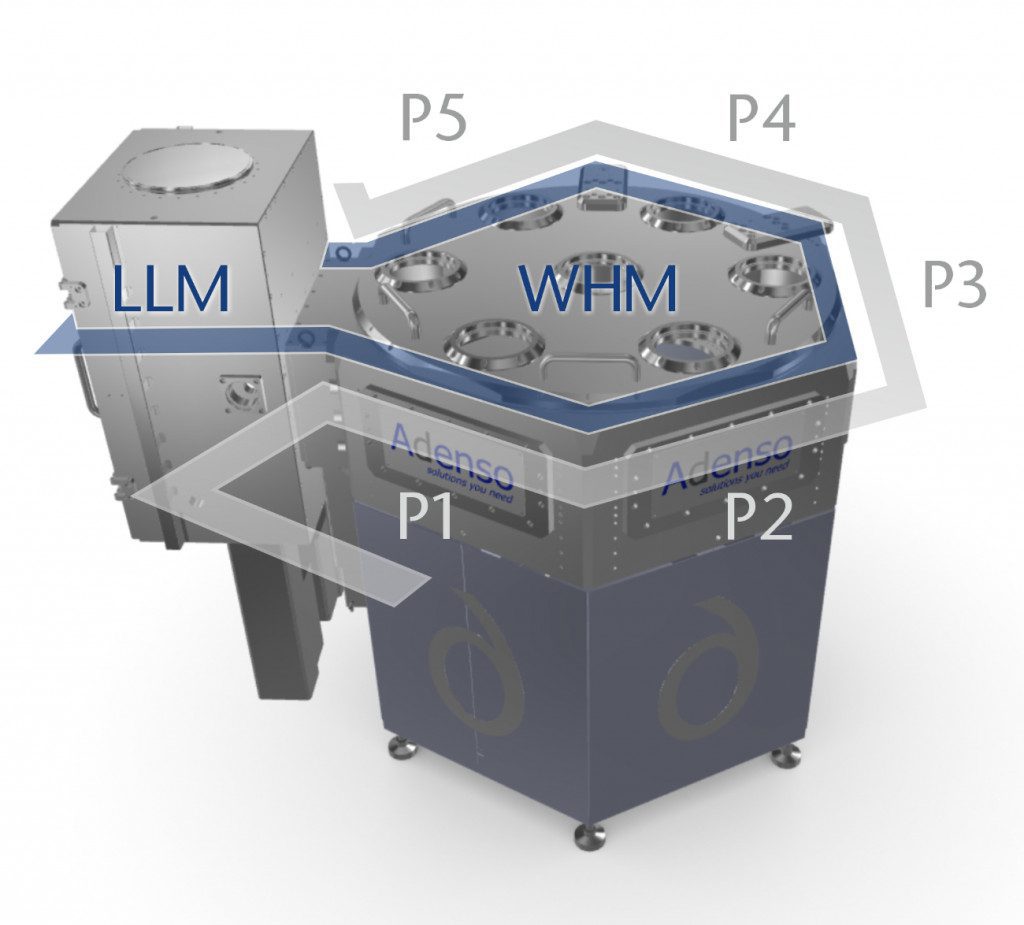

Configuration example of a central WHM WaferHandling.Module with an LLM LoadLock.Module (blue) and possible customer process modules P1-5 (grey).

Task A: CLUSTER CONTROL SYSTEM with adControl and pressure control by adVAC

Task C: PROCESS VISUALIZATION as a stand-alone or optionally integrated in the adControl visualisation by Adenso (tailored solution)

Task D: INTERFACES with the cluster, vacuum and visualisation

All tasks for implementation and production can be defined, ordered and realised independently of each other and the customer’s process control system.

adControl datasheet

ToolCloud – tool monitoring for industry 4.0

The Adenso ToolCloud manages and monitors all Adenso.Solutions throughout the entire product life cycle, from the start of the project through to actual production. All relevant tool data can be flexibly accessed online from any terminal device. Throughput-relevant data such as reliability, error frequency and capacity utilisation are collected, analysed and presented graphically. All action points and idle resources are therefore identifiable at a glance. Improve the efficiency of your tool processes with Adenso

ToolCloud!

“With its ToolCloud, Adenso makes the internet of things comprehensible and tangible in

a simple and helpful way.”

W. Weinrich

Project manager, Bühler AG