Optional Pre- and Post-Processing.Modules

As additional system components of the Adenso VAC.ROBOTICS platform, Adenso offers further optional pre- and post-processing modules for the temperature control of substrates of any size and for precise pressure control.

adHEAT | advanced heating solutions

Numerous processes, such as in SiC technology (silicon carbide), require high process temperatures (> 1,000°C). Untempered substrates require a long heating time. Optimize your processes and save valuable process time with adHEAT. Our HEATING/COOLING.modules can be easily docked onto the Adenso VAC.ROBOTICS platform and are ready for immediate use.

Your advantages

- Simple integration in the Adenso VAC.ROBOTICS platform

- Process optimisation through time savings

- COOLING.Module: Cooling of substrates after thermal processes

- HEATING.Module: Heating of substrates as process preparation

- adHEAT.1kC enables substrates or carriers to be preheated to the required temperature of up to 1,000°C

- Process control by the Adenso cluster Software.Solution adControl

adVAC

advanced Vacuum Pressure Control

adVAC – our solutions for precise pressure control within the cluster system and its individual chambers. Adenso provides solutions that are individually tailored to customer processes.

adJET

advanced DUT pressure control

adJET – our solutions for the targeted provision of special pressure values directly at the Device Under Test (DUT). Gases or gas mixtures can be fed directly to the substrate via a nozzle, independently and separately from their vacuum environment, without spreading in high concentrations in the surroundings.

STEALTH.CARRIER

STEALTH.CARRIER is a special substrate carrier for temperature applications, especially cryogenics, which is almost thermally invisible. The carrier has virtually no heat signature and is therefore particularly suitable for environments with liquid gas such as helium up to 4.2 K. This Adenso.solution can also be used for modified applications such as HOT.TRANSFER or Chuck.Clamping.

Suitable for all substrates:

- 50, 100, 150, 200 and 300mm wafers

- Glass, ceramic, sapphire substrates,

- devices, individual chips, etc.

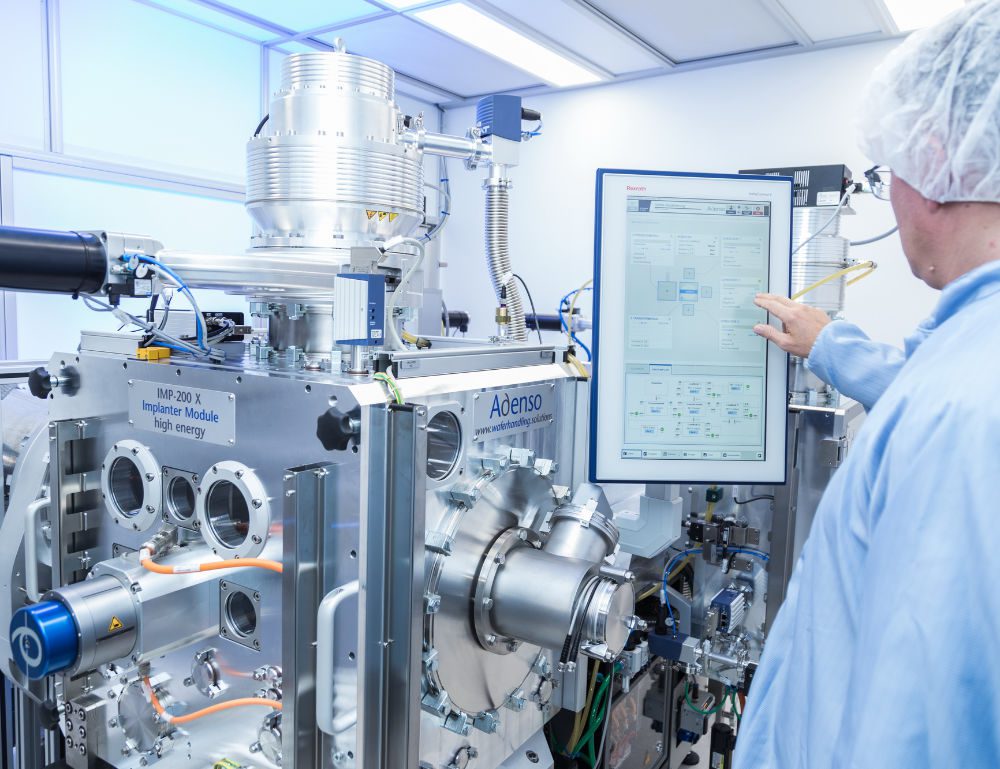

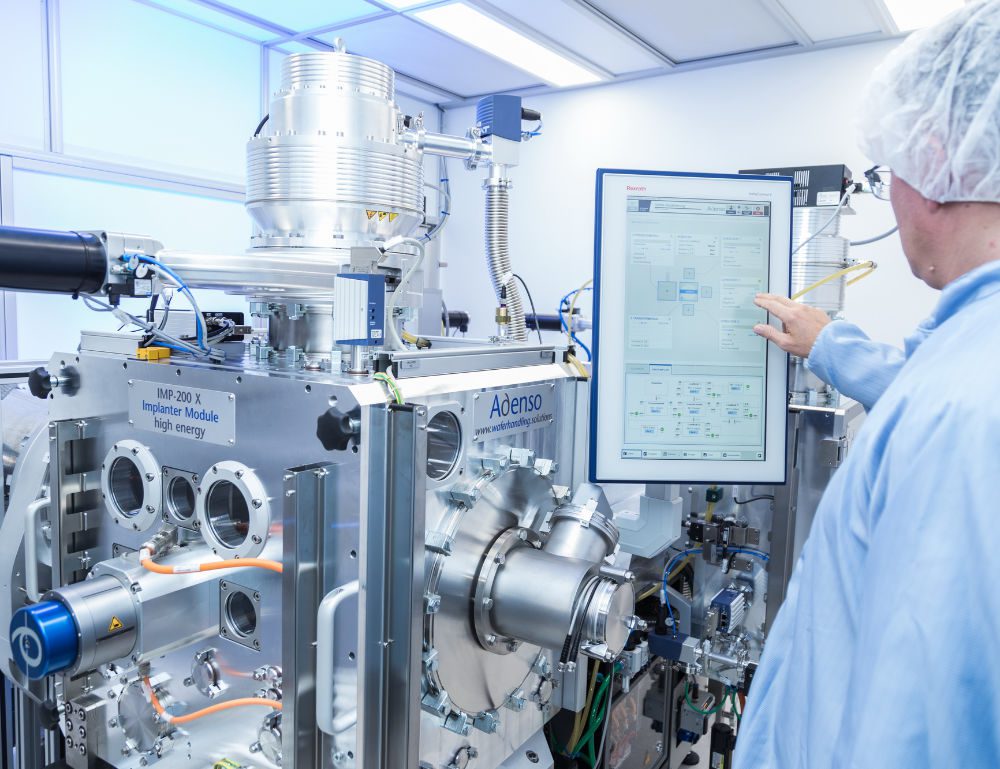

Implanter.Module

During ion implantation in the semiconductor industry, ions are deposited onto and into substrates such as wafers (doping, creating of planned shortcuts, etc.). This enables targeted changes to the properties of the base material and/or the layers that have already been applied. Adenso supports users in the field of ion beam technology: For handling substrates in high vacuum environments, Adenso offers customer-specific implant modules (IMP) as part of the modular VAC.ROBOTICS platform.

The WHM-IMP200X.Module is designed for substrate dimensions of up to 200mm, on which wafer sizes of 150/100/75/50/25mm can also be processed. The WHM-IMP300X.Module with the same functionality exists for 300mm wafers.

Direct substrate handling as well as carrier solutions are available for all substrate sizes and dimensions (round, rectangular, special).

- fast setup and commissioning,

- Simple integration in the Adenso VAC.ROBOTICS platform

- configurations based on approved functions/modules/technologies

SSS SubstrateScanner.Solutions

The following special features are particularly valued by Adenso.Implanting customers

- vertical.scanner – for fast and high precise substrate movements, in case the ion beam can only be formed in one dimension

- DUAL.SCAN Solution – comes with two scanner.modules for highest thruput

- active-/passive-substrate - technology