LLM LoadLock.Modules

Our Adenso LLM 230/330 LoadLock.Modules enable loading of multiple substrates with a MAG magazine or WaferCassette under vacuum environment. All ports of the WaferHandling.Module are equipped with a lockable GATE to keep individual modules separate from each other in vacuum terms. Our WHR WaferHandling.Robot access the respective substrate via this gate valve.

The Adenso Loadlock.Modules

for research and production:

- Semiconductors: Wafers, masks, carriers

- Material research

- Surface analysis

- Nano- and biotechnology: Sample holder

- Sensors

- Optics

- Photovoltaics: Solar cells

- Device test

Your advantages

- Latest technologies

- Compact and stable design

- Low acquisition costs

- User friendly

- Various configuration options

- High productivity and reliability

- Immediate usability

- Ergonomic design

- Integration support

tailored for research and production

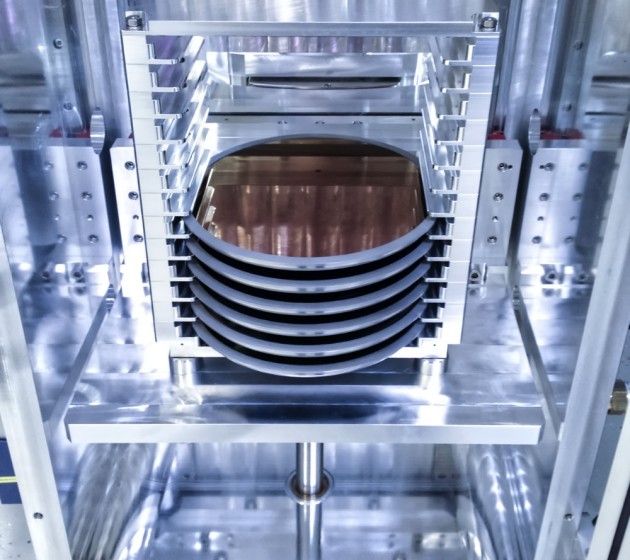

The LLM330 LoadLock.Module is a tailored carrier storage system for research and production. Based on a vertical lifting unit, the module enables continuous substrate handling and thus ensures constantly running processes. The LLM330 load lock module can be used for fully automated loading and unloading of between 5 and 50 substrates/carriers. Weights of more than 10kg per carrier are possible.

- Also usable as a BUFFER.Module

- Optionally with adHEAT heating and cooling options and special adVAC pressure control

MLL ManualLoadLock.Modules

The Adenso MLL 200/300 ManualLoadLock.Modules are suitable for feeding plants with individual substrates or individual wafer carriers as well as small MAG magazines with up to 5 substrates.

- Also usable as a BUFFER.Module

- Optionally with adHEAT heating and cooling options and special adVAC pressure control

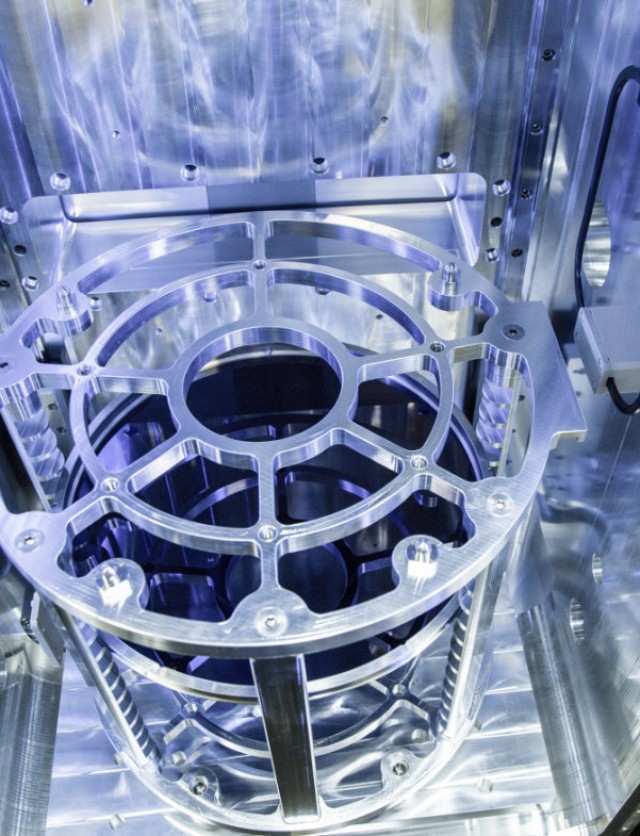

ALM AutoLoad.Modules

The Adenso ALM 230X AutoLoad.Modules close the process gap between manual loading solutions and fully automated WaferHandling.Robot systems. Fast, streamlined, independent, suitable for high-vacuum and cleanroom.

Your advantages

- Process reliability: high-precision and space-saving kinematics, Substrate.Mapping, ID reader for magazine identification

- Flexibility: customised integration of different test devices, image processing systems, substrate alignment of different cassette types

- Suitable for substrates up to 200 mm, round and square type

- ToolCloud: The Adenso.ToolCloud manages and monitors all Adenso.Solutions from the start of the project through to actual production

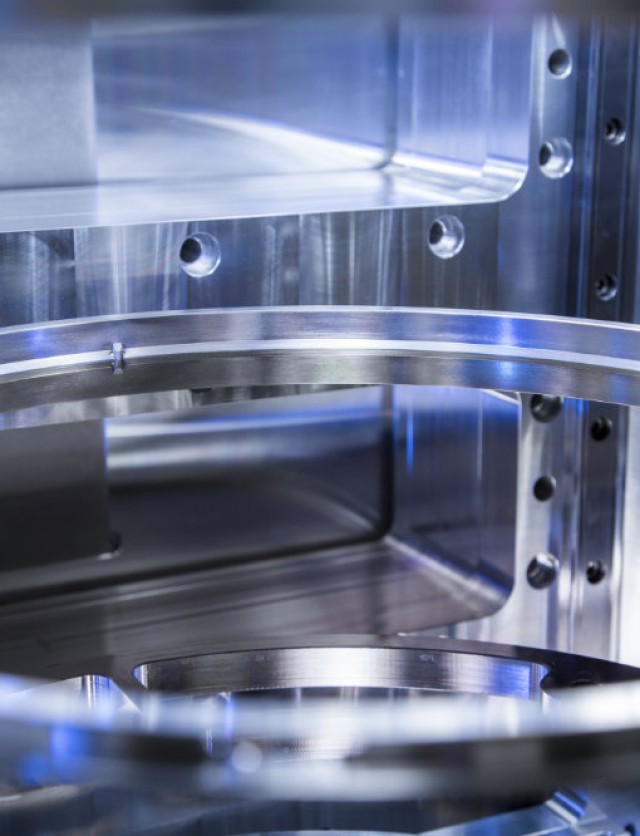

adLOAD | advanced High.Capacity LoadLock.Modules

The Adenso adLOAD LoadLock.Modules offer an enormously high substrate capacity for cluster tools. 30, 40, 50 and more wafers per cycle can be accommodated in a LoadLock – an enormous increase in the autonomous time with the same footprint.

Your advantages

- Compatible with all options of the Adenso VAC.ROBOTICS platform

- Combinable with alignment, multisubstrate gripper, temperature control, etc.

- Also configurable with a substrate size of 200 and 300 mm

- Combination with all central platforms for future-proof flexibility of all applications

- Configure now!

FLP FOUP300 VAC.LOADPORT

The Adenso FLP FOUP300.VAC.LoadPort enables direct loading of a FOUP in a vacuum environment.

- No atmospheric robot handling necessary

- Saves up to 80 percent clean

- Suitable for Lab.Applications