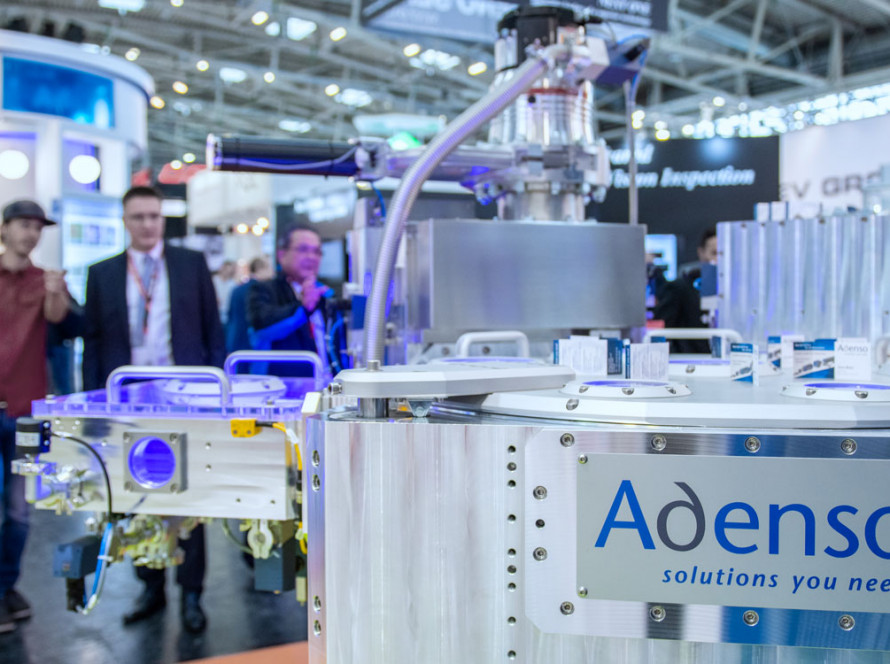

ALM230X closes the gap between the manual loading rail and the fully-automated robot

Adenso SubstrateLoader – rethought and revamped!

“Mind the Gap”

The gap between the manual loading rail and the fully-automated robot in the wafer handling process is well-known. Adenso has closed the gap with the new AutoLoad module.

The new AutoLoader is quick, lean, independent and suitable for both high-vacuum and cleanroom:

- efficient use of space

- economical acquisition and operation

- flexible handling

- suitable for all substrates

- With Adenso Tool.Cloud

- Conceived and made in Saxony

To the new ALM230X AutoLoad Module product

More about Adenso Load.Solutionswww.AutoLoad.solutions

This Adenso innovation had its première on 24+25/01/2019 in Dresden at the “Innovation Forum for Automation”

Using the ALM230X prototype on site, Adenso engineers were pleased to answer all questions. At the forum, there was always a break between the series of talks and the evening event, during which it was possible to learn about the Adenso production processes (all regionally anchored).

The core of the automation industry in Silicon Saxony has banded together in the Automation Network Dresden or AND for short.

Meet Adenso at the 16th Innovations Forum for Automation in the DGUV Conference Center, Dresden.

Your contact and expert at Adenso:

Adenso GmbH

Zur Wetterwarte 27

01109 Dresden, Germany

Email: info(at)adenso.de

Website: www.waferhandling.solutions

Uwe Beier, Managing Director